|

Jiangsu Dawn International Trading Co.,Ltd

|

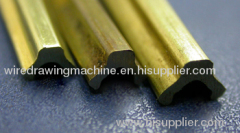

sawing wire drawing machine

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sawing wire

Advantages

The use of ultra tensile technology which allows us to produce very thin and very high tensile wires which result in low ke

Sawing wire

Advantages

The use of ultra tensile technology which allows us to produce very thin and very high tensile wires which result in low kerf loss (and hence more wafers per cut) and less fractures (resulting in a higher productivity)

Tight diameter and ovality tolerances

A wide range of spool types that assures our saw wire can be used on all machine types

An advanced winding technology which allows us to deliver an optimal winding quality

Advantages

The use of ultra tensile technology which allows us to produce very thin and very high tensile wires which result in low kerf loss (and hence more wafers per cut) and less fractures (resulting in a higher productivity)

Tight diameter and ovality tolerances

A wide range of spool types that assures our saw wire can be used on all machine types

An advanced winding technology which allows us to deliver an optimal winding quality

Product description

Sawing wire is a high grade steel wire that can be used to cut a wide range of products. It serves as the abrasive carrier in a Multi Wire Saw.

The technique finds its origin in the world of solar cells. From the mid eighties, this technology was developed to decrease kerf loss and increase productivity. In the early nineties the method was also introduced for slicing silicon ingots to wafers for the electronics industry. Since then the technique has been more and more introduced for cutting other hard and brittle materials as well.

Saw wire

Saw wire is used to cut a wide variety of products, such as silicon, germanium, gallium aresenide, quartz, indium phosphide, to name only a few. Saw wire is mostly used in the production of solar cells.

The use of photovoltaic energy is increasing, as humanity becomes more and more aware of the scarcity of the natural resources. Especially, the leaders of developing countries realized that the use of photovoltaic energy supports their race towards improving the standard of living.

A world without technology can hardly be imagined anymore. The advances in technology we know today are based on the development of semiconductors, which can be found in every kind of microelectronic applications, such as computers, consumer electronics or cars to name only a few.

The use of photovoltaic energy is increasing, as humanity becomes more and more aware of the scarcity of the natural resources. Especially, the leaders of developing countries realized that the use of photovoltaic energy supports their race towards improving the standard of living.

A world without technology can hardly be imagined anymore. The advances in technology we know today are based on the development of semiconductors, which can be found in every kind of microelectronic applications, such as computers, consumer electronics or cars to name only a few.

Saw wire for high quality wafers

WireSolutions' superior saw wire is used to cut the silicon wafers, which are the building blocks of the fragile photovoltaic solar cells or semiconductors.

WireSolutions' consistent high quality saw wire offers the necessary characteristics wherever it is used. Our wire is available in various diameter and tensile strengths, in every length up to 640 km and on a variety of different spools.

Our innovative TA100 spool and various other current spool developments will increase this length even further. Longer lengths allow for more efficient and cost effective production runs.

WireSolutions' consistent high quality saw wire offers the necessary characteristics wherever it is used. Our wire is available in various diameter and tensile strengths, in every length up to 640 km and on a variety of different spools.

Our innovative TA100 spool and various other current spool developments will increase this length even further. Longer lengths allow for more efficient and cost effective production runs.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Copper Wire Drawing Machine

Sawing Machine

Band Sawing Machine

Metal Band Sawing Machine

Vertical Sawing Machine

Drawing Wire

More>>